Marillana Bridge Bearing Replacement

Marillana Bridge Bearing Replacement

Description:

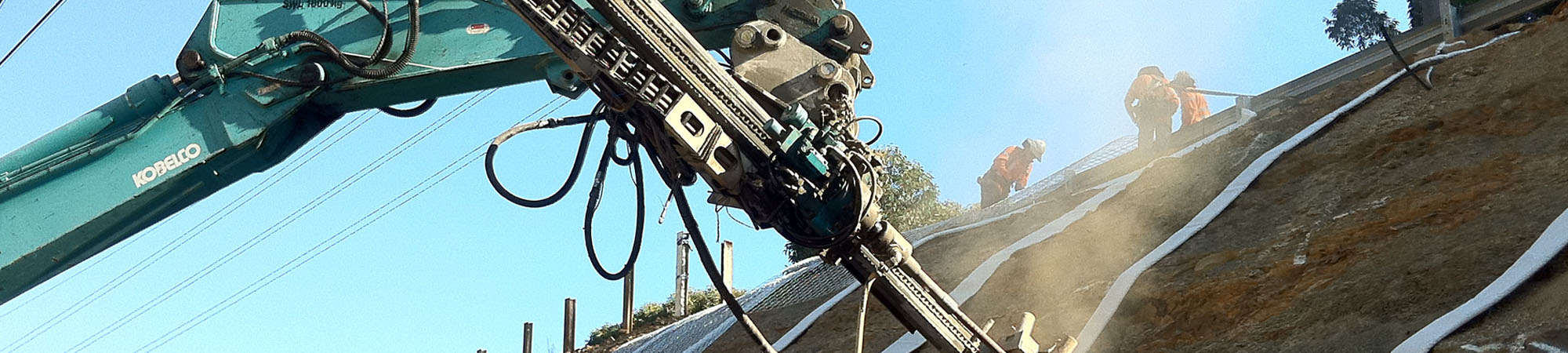

The project came with some unique issues and Freyssinet was contracted by BHP to initially design access platforms around the piers that will be utilized as working platforms during construction and as permanent platforms for asset inspections by BHP. Then, to design a method for replacing the bearings and execution of the works. The existing bearings prematurely needed replacement due to an increase in loading on the bridge and to comply with new design standards. Freyssinet approached AECOM as consulting engineers to analyze the structure and calculate the bearing loads. FPC designed and supplied the new bearings with the calculations provided by AECOM. FITS, AECOM and Freyssinet worked together to design a method for jacking the structure within the constraints of the client and the geometry of the structure. With the increased axle loadings, the bearings required additional fixings to resist the forces and extra bolted connections had to be created between

the bearings and bridge girders.

Key Aspects:

Freyssinet scope of works included design, supply and installation of new access platforms and replacement of spherical bearings.

Freyssinet designed, delivered and executed the works within the time specified by BHP.

Tight timeline allowing 7 days shutdown to jack the bridge by 30mm, remove the existing bearings, demolish the grout pads, replace the 32 new bearings at 7 piers and 2 abutments, recast grout pads under new bearings, cure grout and lower the bridge back to its position.

The bulk of the installation works was done outside the shutdown period. Freyssinet handed the completed bridge back to BHP 24 hours early.

Print Friendly: