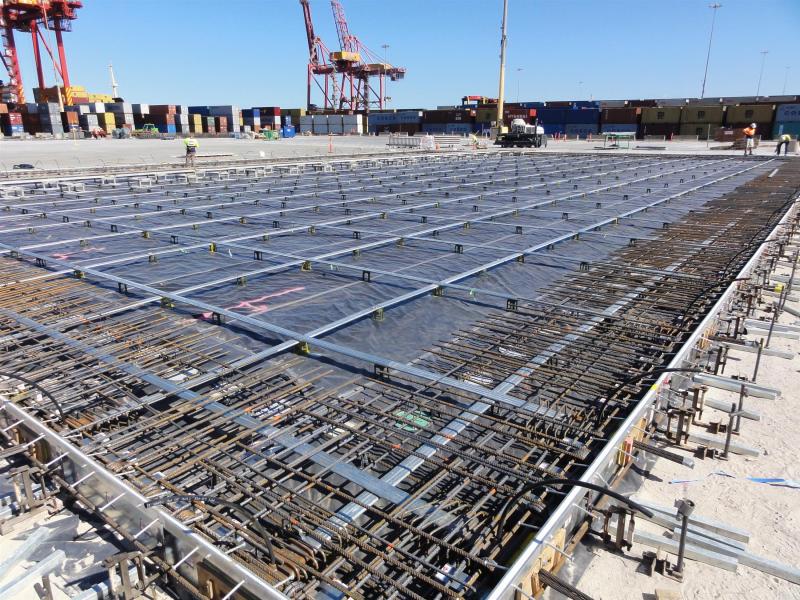

Slab On Ground

Slab On Ground

Post tensioning brings a number of unique benefits to the design and construction of slab on ground applications.

Common issues involved with the construction of slabs on ground include:

- Any mass pour concrete is subject to creep and shrinkage during curing, which can lead to cracking if uncontrolled.

- Slabs are particularly susceptible to cracking. The most common way to control this is with regular joints, either saw cuts or full expansion joints at typically 6-8m spacing.

- This leads to both large construction costs, up to 20% of initial construction value, and significant long-term maintenance costs.

- Joints also place limits on use of space.

By utilising a post tensioned slab on ground solution, the following benefits can be achieved:

- Significant reduction in joints bringing cost savings and improvements to operational performance, particularly in slabs with high traffic movement.

- Standard tendon lengths are 60m, compared to joint spacing of conventionally reinforced slab of 6-8m.

- 2,000-3,000sqm joint free pours are typical, up to 6,000sqm has also been achieved.

- Reduction in long term maintenance requirements due to reduced joint requirements, indicatively up to 60% cost saving.

- Increased loading capacity or reduction in slab thickness with significant material savings.

- Increased durability.

Typical applications for post-tensioning slabs on ground include:

- Logistics warehouses.

- Distribution centres.

- Bulk solid stores.

- Maintenance facilities.

- Refrigeration stores.

- Container handling facilities.

- Special applications.