Port Lincoln – BLP Painting Rectification – Trestles 13-15

Port Lincoln – BLP Painting Rectification – Trestles 13-15

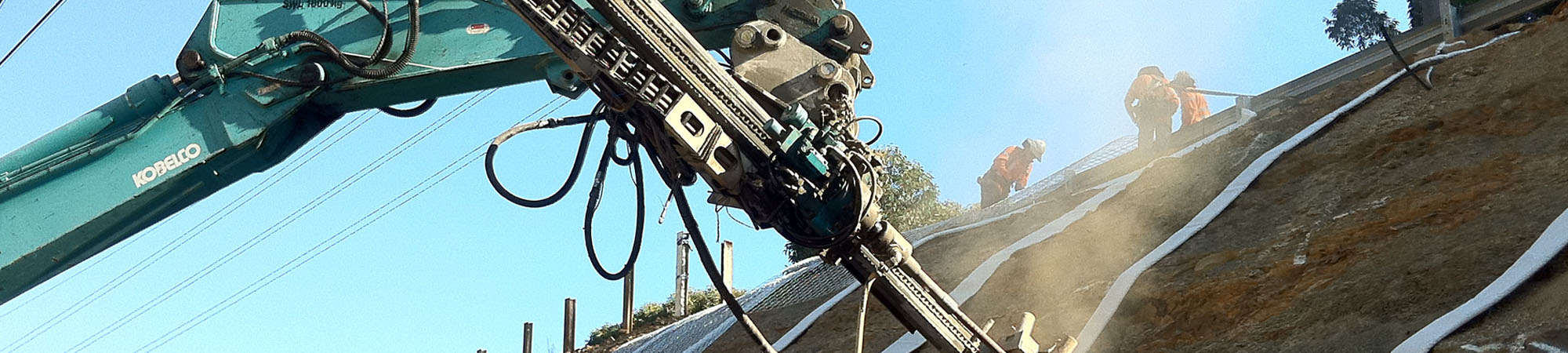

This project involved general painting rectification to several parts of a conveyor structure on the Port Lincoln Wharf for Viterra. The project items to be undertaken by Freyssinet Australia were started and finished within a shutdown period and so the entire project was under a tight and critical program. However, the team managed to deliver it on schedule despite setbacks from heavy wind and rain during the project.

The works started with the erection of a scaffolding system for two out of the three sections to be remediated, with the other section to be done from EWP due to the angle of the section. The scaffold was completed by the Freyssinet subcontractor Complete Scaffolding who managed to hand over the scaffold before the deadline date of the shutdown. This allowed Freyssinet a few shifts to ensure they were on schedule; especially as extra corrosion removal and surface preparation had been identified.

Freyssinet’s work was to power tool clean and then prime corroded areas or areas where the paint was badly adhered, and then apply another coat of the Interplus 356 to the entire structure in each section. This was followed by a top coat of Interthane 990 to finish of the coating system. Following this, after the shutdown dates were over and the scaffold cleaned, the scaffolding itself was removed by Complete Scaffolding.