Liddell Reclaim Tunnel Repairs

Liddell Reclaim Tunnel Repairs

Description:

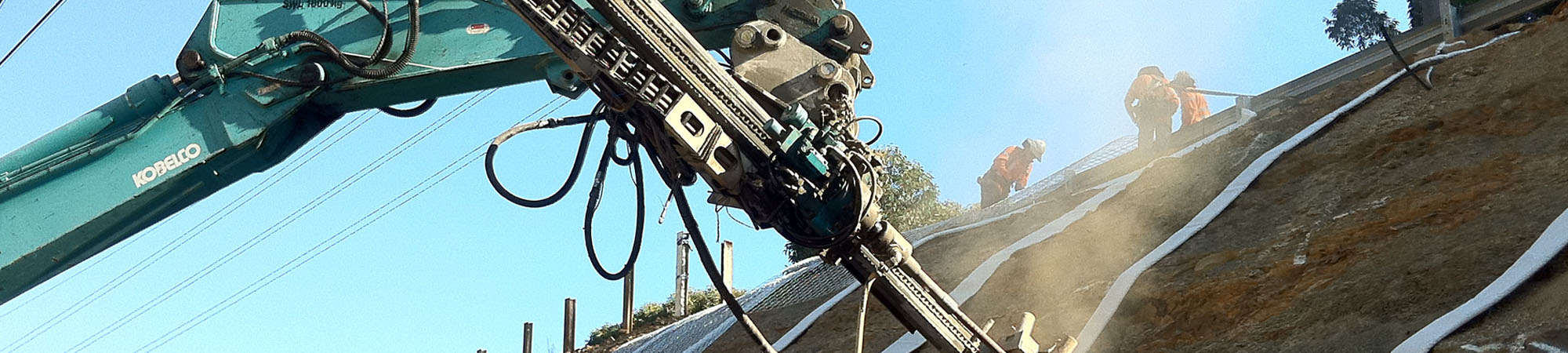

The Reclaim Tunnel, constructed around 1980, is a reinforced concrete structure that houses the reclaim conveyor. The tunnel has a series of valves which feed coal from the stockpile above onto the reclaim conveyor for conveyance to the Coal Handling and Preparation Plant.

The Reclaim Tunnel is subject to the loading from the stockpile above and the equipment used to reclaim the coal, normally a dozer.

We were advised that the No 1 Reclaim Tunnel may have a limited design life of 5 years.

Due to the range of damage that has occurred, the extent of repairs were varied, and were classified into three general categories:

Key Aspects:

Slight damage that did not warrant repair at this stage, however, needed to be monitored, reinspected and reassessed at regular intervals. If reinspection indicated that deterioration of the damage had occurred, then the damage would be reassessed at that stage.

Moderate-to-severe damage that is dry and not subject to water ingress. This is generally damage that is not affected by water, (i.e. the cracking or damage does not extend to the outside of the tunnel). This cracking or spalling damage may be repaired using conventional concrete repair methods. Cracking would be repaired by crack injection of epoxy using a proprietary epoxy system. Spalling would be repaired using a proprietary cementitious mortar repair system.

Moderate-to-severe damage that is subject to water ingress, and the substrate is generally wet. Under these conditions, a specialist product is required to allow the repair to be carried out under wet conditions. Parchem, a specialist supplier to the building industry, has a crack injection system that can cure in wet conditions which requires installation by experienced personnel.

Print Friendly: