Hammondville Elevated and Surface Reservoir Roof Renewal & Relining

Hammondville Elevated and Surface Reservoir Roof Renewal & Relining

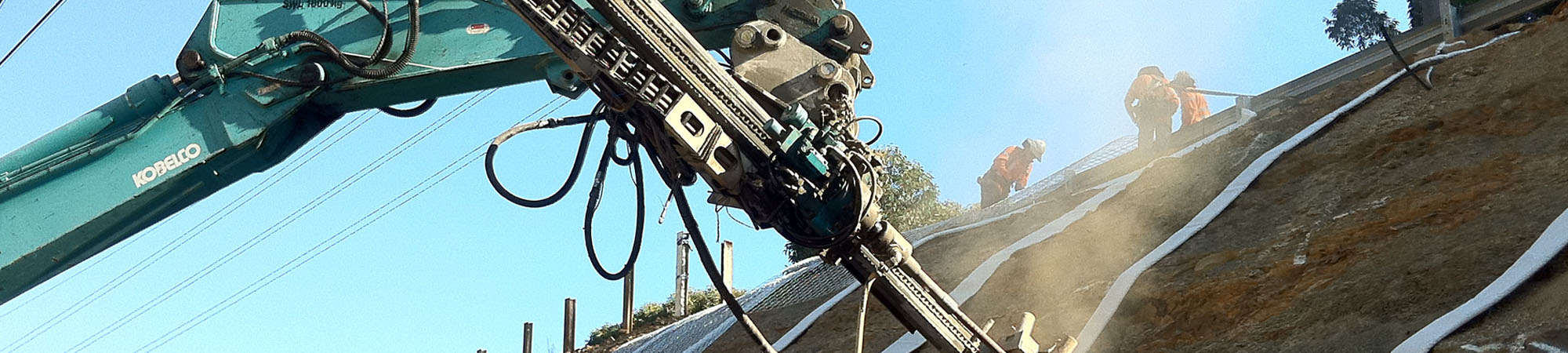

The project comprised the refurbishment and equipment upgrade of two reservoirs. The tanks were constructed in 1972 and are part of the Prospect South Water System owned and operated by Sydney Water.

The surface reservoir is a circular steel reservoir with a diameter of 30.5m, a wall height of 12.3m and a storage capacity of approximately 9ML. Due to high level of corrosion and damage on the roof structure, Freyssinet Australia was engaged to perform refurbishment works to the roof structure and a full relining of the reservoir.

The elevated reservoir is a circular steel reservoir with a diameter of 9.8m, a wall height of 3.8m and a storage capacity of approximately 0.23ML. The tank is supported by a 16.4m high steel braced tower consisting of a central column and eight perimeter columns. The roof structure failed all testing performed and needed to be entirely replaced along with an important refurbishment of the external supporting structure.