Actiflo 3B Blast and Paint Setting Tank

Actiflo 3B Blast and Paint Setting Tank

Bayswater cooling water treatment plant uses Actfiflo’s plant for removing turbidity from the cooling water before further processing of the water.

The Actiflo process comprises coagulation, injection, maturation and laminar settling. All of these processes are carried out in one tank which has separate sections for each individual process treatment. The process uses ferric chloride solution as the coagulant and polymer agent for flocculation along with micro sand for faster sedimentation of the floc.

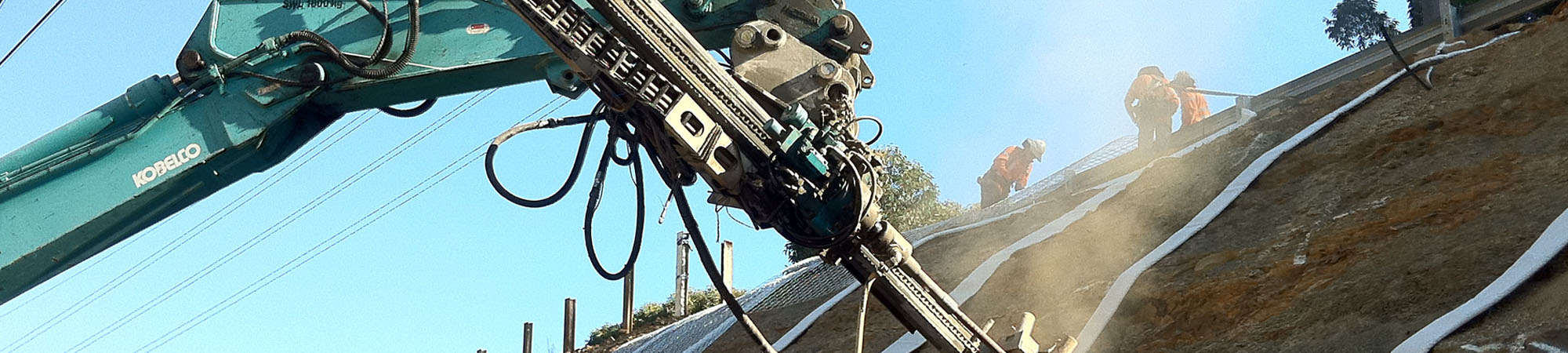

The Actiflo tank has issues with the current epoxy based protective lining which has deteriorated at a number of locations within the tank and has failed. AGL Macquarie intends to completely reline the tank including its internal partitions and structural supports at the top so as to protect the parent metal and integrity of the vessel.

The scope of work for one Actiflo vessel included:

- Remove current epoxy by appropriate means of pressure/grit blasting.

- Thoroughly clean the tank from inside of any rubbish, loose linings or aggregate materials.

- Prepare the surface for the application of the principal approved protective lining.

- Any minor internal surface preparation work if required (e.g. filling of pits using approved metal putty or equivalent material).

- Apply protective linings.

- Carryout NDT on the lining and provide detailed report.

- Dust containment during the work.