SR01 & K8 Wharf – Asset Integrity Painting

SR01 & K8 Wharf – Asset Integrity Painting

Description:

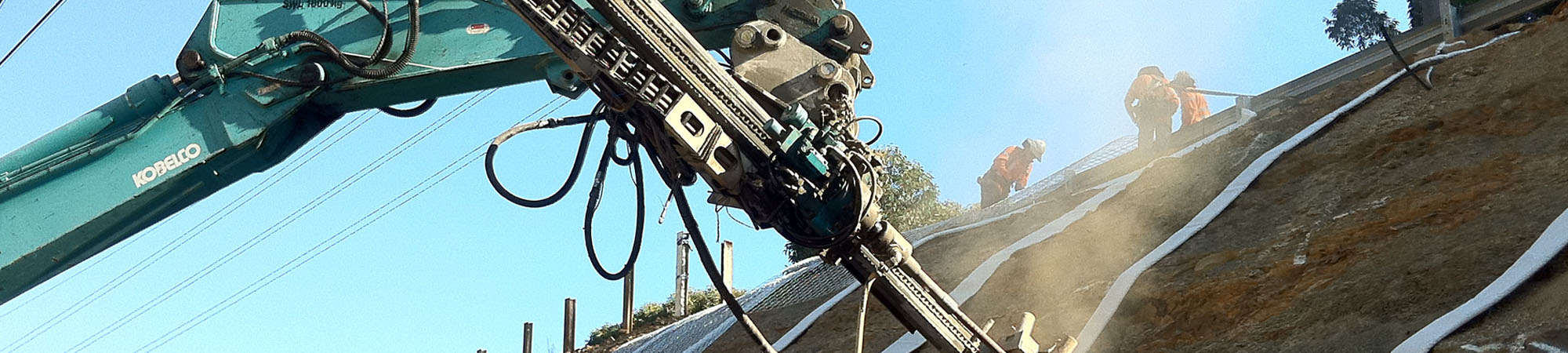

NCIG owns and operates one of Australia’s major coal export terminals and is currently located on the Kooragang Island in Newcastle, NSW. The NCIG plant and equipment was constructed over a period of three years circa 2010 and it now reaches a maximum capacity of 66Mt of coal processed and exported per annum.

The project is part of a long term coating maintenance plan on NCIG assets that include stacker reclaimers, ship loaders and wharves, in order to adequately maintain and increase the life expectancy of their large pieces of plant. Freyssinet Australia was awarded the first stage of the works which involved coating maintenance on SR01 stacker reclaimer and a portion of K8 wharf.

Key Aspects:

The project was approached in two separate phases:

1) Coating works on a section of K8 wharf:

Completion of spot repairs on critical parts of the structure (pylons, beams, etc.) via power tool clean and conventional spray.

All works were completed via boat access with mobile scaffold built on boat.

Large repairs were completed on the fender pylon via abrasive blasting and airless spraying.

Large defects were thought to be due to impacts from other vessels which lead to further deterioration of the coating with time.

The main challenge for phase of works was to ensure there was no discharge of debris / contaminants into the Hunter River whilst conducting the works.

The works were also impacted by the shipping movements (ships berthing and departing) during which works had to cease for safety reasons.

2) Coating works on SR01 stacker reclaimer during a 10-day outage (24-hour work schedule):

Spot repairs were completed on the boom structure via power tool clean and brush / roller application, with access via EWP or from mobile scaffold / walkway.

Large spot repairs were completed around the bucket wheel area via abrasive blasting and airless spraying.

A large scaffold with full encapsulation was installed around the bucket wheel area in order to contain dust emissions from the abrasive blasting process.

The main challenge for this portion of work was to complete the scope of work before the re-commissioning date of SR01, despite being heavily impacted by inclement weather events during the outage (high winds and rain).

Both phases of work included the provision and installation of temporary site facilities and full-time supervision and project management.

Print Friendly: