Parramatta Light Rail HPL Pipeline CP and Coating Upgrade

Parramatta Light Rail HPL Pipeline CP and Coating Upgrade

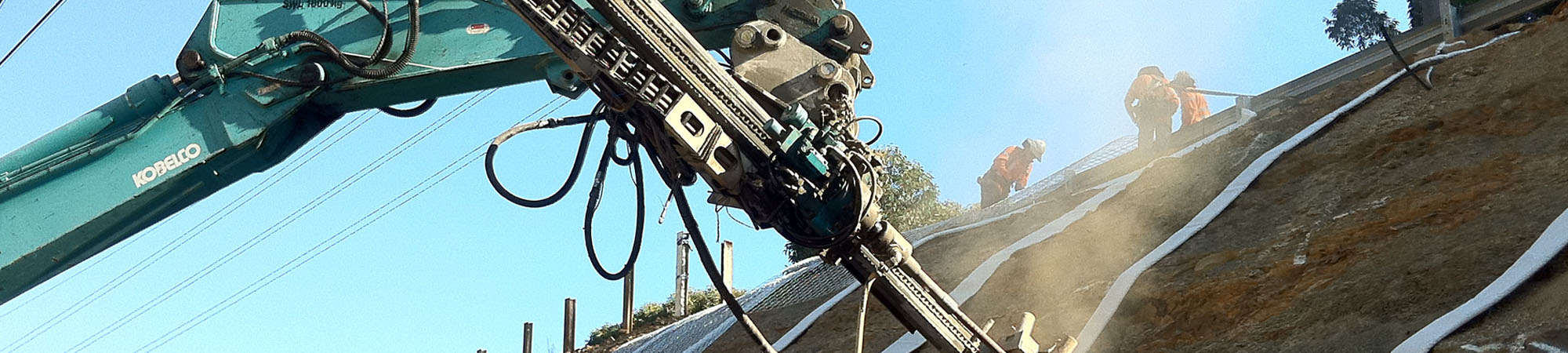

This project was to conduct a condition assessment of the Caltex pipe that ran through the track of the new Parramatta Light Rail. Caltex had instructed CPBDJV that to install the tracks over the pipe, a reinforcing slab was required over the pipe to protect it from any damage due to light rail traffic etc. Prior to this, Caltex also required the pipe to be assessed by pipeline integrity engineers (AMSPEC) and then recoated by Freyssinet Australia and cathodic protection installed also by Freyssinet.

To get to the pipe, another subcontractor had to excavate a 4-5m deep trench, which involved lengths of up to 32m in one section and 15m in another. The subcontractor provided a wide trench at over 4m wide at some points, with very good shoring in the form of massive steel shorting plates and beams. The trench was professionally constructed with two safe access points and two rescue winches (although the trench wasn’t considered a confined space for emergency purposes).

After Freyssinet completed their CP and coating works, the client backfilled the trench with Caltex monitoring the backfilling to ensure no damage occurred to the pipe and new coating system.